Most painters have a sense of how to prepare panels for oil and acrylic paintings when they are meant to be shown indoors, and we even published a couple of Just Paint articles on the topic:

Understanding Wood Supports for Art – A Brief History

Plywood as a Substrate for Painting

However for both Muralists and Sign Painters questions can quickly arise when preparing panels for a life outside, where rain and humidity are a constant threat. What follows are our best recommendations drawn from industry research and our own field experience over the decades.

The first step, before anything else, is making sure you use an appropriate plywood as not all of them are made for extreme changes outdoors. We would strongly recommend working with either a marine grade plywood or a type of plywood called MDO (Medium Density Overlay), often referred to as sign painter’s board. Good lumber supply stores should be able to help you select one that is appropriate.

To prepare the panels for outdoors you will need to seal them as much as possible from moisture, especially along the sides, where water will easily penetrate. Below are the steps we recommend:

1) Make sure the surface is clean and free of any dirt, wax or oils.

2) Lightly sand all smooth surfaces to assure the primer has good adhesion.

3) Apply a minimum of two coats of a high quality alkyd-based exterior wood primer to all surfaces, including the edges and both the face and back. Exterior alkyd primers are available from most good commercial paint stores.

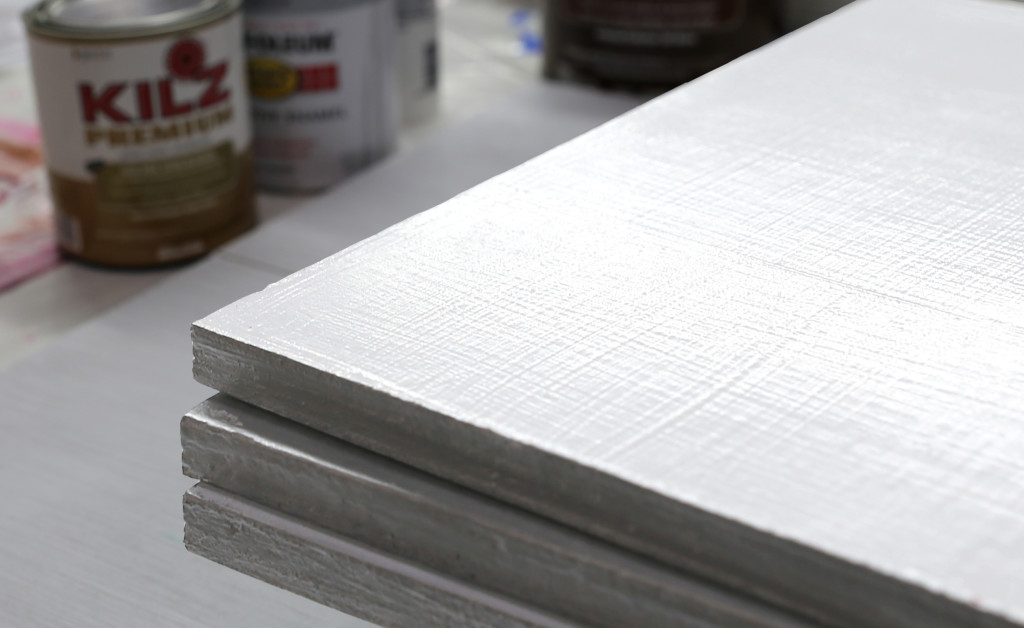

4) After the above has fully dried, seal the edges with an aluminum paint made from aluminum flake or leaf. This has consistently been shown to be the most effective moisture barrier when comparing various coatings.1 Most major manufacturers such as Sherwin-Williams®, Benjamin Moore®, PPG®, and Rust-oleum® produce these, where they are commonly used for marine, metal, or automotive applications.

5) Finish by applying a high quality exterior latex primer to the front and back of the panel. This will give additional durability and assure having a nice, bright white ground to paint on.

Once the panels are fully dry, follow the guidelines provided in our Exterior Mural Tech Sheet, paying particular attention to the recommended list of colors:

Once the mural is finished, you should apply an Isolation Coat and two or more coats of our MSA Varnish. For information on these, please see our MSA Varnish and Isolation Coat Tech Sheets, as well as our Mural Resource Guide:

As always, if you have further questions, please contact our Materials and Applications Specialists by email at help@goldenpaints.com, or call 800-959-6543 / 607-847-6154

1 See Williams, R. Sam. “Chapter 16: Finishing of Wood”, Wood Handbook, Madison, WI, Forrest Products Laboratory, pp. 13- 15. http://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr190/chapter_16.pdf

About Sarah Sands

View all posts by Sarah Sands -->Subscribe

Subscribe to the newsletter today!

Re waterproofing panels for indoors. I saw the following post by Sarah. Is shellac a reliable surface to paint on then, if it gets brittle with age, isn’t the painting at risk? Might be better to skip waterproofing? Is it mostly to stop warping? Ditto is an aluminium coating instead of shellac going to last? Advise often is use artist products because commercial formulations can change recipes and aren’t intended to last so long. If the primer fails, the whole painting fails. Are there other alternatives that are likely to last longer? Do you then put gel or gac100 on top of that? Thanks

Hi Ralf –

Thanks for your questions. Just so others know the context, the quote you share is from a reply I posted in a thread on MITRA (Materials Information and Technical Resources for Artists) which they can read here: https://www.artcons.udel.edu/mitra/forums/question?QID=379

Let me reply to your questions individually:

Is shellac a reliable surface to paint on then, if it gets brittle with age, isn’t the painting at risk?

Might be better to skip waterproofing? Is it mostly to stop warping?

Ditto is an aluminum coating instead of shellac going to last?

Advise often is use artist products because commercial formulations can change recipes and aren’t intended to last so long. If the primer fails, the whole painting fails. Are there other alternatives that are likely to last longer?

Do you then put gel or gac100 on top of that?

Hope that helps!

Where can I get the primers? I am working on an outdoor mural on a large scale plywood sheet and I am researching the best combination of materials to use. I am interested in using your paints but I am wondering what products work best with your paints as in primers, aluminum paint, latex, isolation coat and varnish. Thanks for your help!

Hello Cameryn,

when buying commercial products for the first time, we recommend going to a good hardware store and getting advice there. In general building materials are competitively priced, therefore the price also reflects quality to some extent. As long as the instructions of the commercial primer indicate that it can be top-coated with ‘latex paint’, then our acrylic paints should be fine to use. Besides proper priming, the choice of wooden panel is also very important. We have seen and written about a common problem that occurs with plywood when used for the outdoors here: Surface Checking and Plywood, Is It a Concern? (https://justpaint.org/surface-checking-and-plywood-is-it-a-concern/)

A better alternative to plywood would be MDO panels. If getting new panels is not an option, due to costs, you could adhere a sheet of polyester sail cloth onto the plywood. The plywood then would still likely check and deform, but the polyester canvas would give the painting some additional stability and prevent the cracking from transferring through the paint layers. We have not tested this specifically, but applying paper or canvas over wooden panels has been a common surface preparation technique for centuries.

Please, also take a look at our mural tech sheet for a list of color we specifically recommend for the exterior: https://www.goldenpaints.com/technicalinfo/technicalinfo_murals

Should you have more questions, feel free to email us at help@goldenpaints.com.

Best of success with your mural!