Paint Additions Into GAC 800 for Pouring Applications

Several rounds of test mixtures of GAC 800 and GOLDEN paints.

By far, the most popular GOLDEN Acrylic Medium used for pouring paints is GAC 800. Our Heavy Body Acrylics, Fluid Acrylics, and High Flow Acrylic paint lines readily blend with this free-flowing medium. These mixtures will merge together well due to the uniform consistency and provide excellent control of line and edge. Because these paints are so highly pigmented, one only has to add a very small percentage to GAC 800 to yield vibrant color fields. When stronger color concentration or increased opacity is desired, higher amounts of paint may be added as needed.

A previous Just Paint article about Pouring mentions a 10:1 (GAC 800 to paint) ratio as a good starting point. At this level, the paint additions are not likely to alter the medium’s sheen, consistency, and inherent application properties. There’s no true right or wrong paint level when it comes to mixing into GAC 800. However, increasing the paint levels will eventually begin to impact the medium’s ability to flow and dry defect free. So the question becomes, “exactly how much paint can I add before GAC 800’s pouring ability is compromised?”

Being the ever-inquisitive paint geeks that we are around here, we set up some testing to help answer that question. Since each paint line has a defined set of properties, it was necessary to take a look at each of them separately. The same colors (Burnt Sienna, Carbon Black, Titanium White and Phthalo Blue / Red Shade) were used for each line, helping to reduce the variables. We also used ratios of paint to GAC 800 that went well beyond what we recommend for pouring as a way to establish an upper limit. However, each artist might want to do their own testing, especially if using colors beyond the ones we chose.

Heavy Body Acrylics

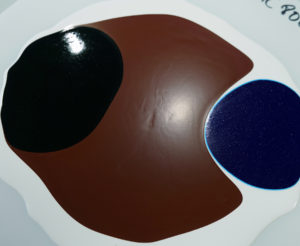

Heavy Body Acrylics are obviously much thicker than GAC 800, and when added at higher levels, can make it so thick that it will no longer pour. Each pigment possesses inherently unique properties which became obvious when testing a small set of four colors. Since paint formulas differ from one to other, you should test everything you would like to use to make sure it performs as expected. In the latest testing, each Heavy Body color still remained pourable at 2:1 (GAC 800 to Heavy Body), with some more pourable than others. At a 1:1 ratio (see image 1), all of the mixtures were unable to flow and level readily. They didn’t craze, but for pouring purposes, these ratios are not useful.

Fluid Acrylics

Fluid Acrylics are the closest paint line with the consistency of GAC 800. However, as more paint is added to the mixture, they start to behave differently. At a 1:1 ratio the paint sheen is affected, with bubbles less willing to come out and the retention of “motion lines” that result from how the product was applied. Also at these higher paint levels, puddles can create slight depressions, the beginning signs of crazing, along with the color borders (see image 2). Even single paint pours at these elevated levels are more likely to craze (see image 3).

High Flow Acrylics

High Flow Acrylics are thinner than GAC 800, so mixtures become thinner and flow readily. At lower levels, this makes for some great blending and movement with little effort. As the paint levels are increased, the mixtures remain craze free, which makes sense when you consider that the pours are physically thinner and thus dry more uniformly throughout the entire paint film. Upon drying, it was noted that higher paint percentages developed surface defects. Some of the additives in the paint, even the pigment itself, can “kick out” and congregate on the paint surface. Retarders and surfactants were observed (see image 4). When these kinds of materials are allowed to remain on the surface, they can cause foaming and adhesion issues for subsequent paint layers, isolation coats, and varnish. Luckily most of these additives can be readily removed with a soft, damp cloth once the surface is fully dry. However, care must be taken as wiping a freshly painted surface could cause some color lift or surface abrasion. Ultimately, much of this is caused by pouring overly thick layers of paint. Backing off from higher additions of paint levels is the most direct way to avoid these issues.

The Benefit of Increasing Paint amounts

Aside from the issues caused by increased percentages of paint, there are also benefits from these higher paint concentrations. Inherently transparent pigments – such as the entire Quinacridone family – appear more solid and opaque. When pouring solid color wet into wet, there is a cleaner, more distinct border between the pours. Lower ratios of paint with GAC 800 are more transparent and this causes more “ghosting” along the edge (see image 5). Ghosting also happens when paints are layered a bit too quickly or the surface isn’t level. If you desire very clean edges, allow each poured layer a little time to even out and stop spreading before the subsequent paint is drizzled on.

Stirred, Not Shaken

During testing, we commonly observe interesting, unexpected oddities. One such observation stemmed from shaking each of the paint and medium mixtures the day before applying them (see image 6). In each case, there were more foam bubbles than expected, especially when compared to mixtures that were stirred. After noting some unexpected surface defects in mixtures with Carbon Black, additional testing was conducted with the only difference between getting a smooth, uniform puddle of black and one that looks more like an old urban, sun-baked tar rooftop was that one trial was mixed by simply stirring and the other vigorously shaken. More testing is on the docket, but for now, I’ll take my pouring mixtures stirred, not shaken.

Conclusion

Overall, the main takeaway is to appreciate that lower paint additions, generally from 10:1 to 2:1, are more likely to maintain a uniform, glossy surface that is craze free with minimal differences from color to color. As the paint level increases, so will the differences of how each mixture flows and interacts with other mixtures.

For further reading, visit goldenpaints.com to review the GAC 800 Product Information Sheet. Call or email us at help@goldenpaints.com.

About Michael Townsend

View all posts by Michael Townsend -->Subscribe

Subscribe to the newsletter today!

I love this information I just received samples of both and now I won’t make a mistake with the mixing ratio love the marker and your paint, beautiful bold Colors that can be mixed easily! Wonderful products!

Thanks for the samples and God bless 😇

Thank you, Sharon!

I appreciate the comments.

– Mike Townsend

Thanks Michael! I enjoyed reading the article and always collect these great bits of information…

Cheers!

Thank you very much, Sarajo!

– Mike Townsend

Hi Michael,

I found your experiments very helpful. This info will certainly help me when I start exploring “pour painting” soon. Is this the “pouring medium” almost every artist mentions in their youtube videos?

Thanks for this article. Cheers, D

Hello, Dolores.

Thanks for the kind words and I’m glad you found the information helpful. “Pouring Medium” has become a somewhat ubiquitous term used to define any medium used for pouring, such as Liquitex’s Pouring Medium, GAC 800, Elmers Glue-All, Floetrol, etc. Most can be used similarly but they will not all produce a long-lasting durable film. However, we can only speak to our own product and state it’s a great medium for doing color pours and should hold up well to the tests of time.

I can tell you that Elmer’s said they don’t recommend using their glue as a pouring medium. It not only can yellow, but can become brittle with age. Not to mention that it can absorb moisture.

Hello Crystal!

These are all important facts about the use of PVA glue as a pouring medium. I’d assume if one contacts Flood about Floetrol being used as a pouring medium, they would also caution using it in a similar manner.

– Mike Townsend

I’m curious to know more about the shaken mixture. How many days did the mixture sit before being applied? Do you think given more time to settle, the shaken mixture would produce better results?

Thanks!

Hello, Seth.

Thank you for your questions.

Shaking the paint mixture of Fluid Carbon Black and GAC 800 generated a much higher amount of foam bubbles compared to stirring the same mixture. In the first application, I applied both after mixing, and then for the next several days, I applied pours of the shaken mixture. Even after several days of rest, there were still more bubbles remaining than the stirred mixture (that was applied right after mixing it up). It is possible that this is due to the Carbon Black paint and might not be indicitive of what will happen with other colors, but that testing still needs to happen.

– Mike Townsend

Can you say if Golden is doing any testing with how silicone (as you must know, now a very popular additive in acrylic pours) affects the longevity of GAC800?

Hi, Crystal.

Thanks for your questions. At this time we do not have any conclusive testing to show whether or not the addition of silicone is going to impart any short or long-term paint film stability or adhesion issues. We hope to provide such test results in the future!

– Mike Townsend

Thanks for the information

I’ve been using GAC 500 for pour onto sketch book covers with fabulous results

Care to comment on this vs GAC 800

I can provide photos

Hello Deb.

Thanks for your question!

There are certainly many acrylic mediums that may be used for pouring acrylics. GAC 800 is the least likely to develop crazes, but GAC 500 could be used if the paint layers are kept thin so they can dry evenly. I’d recommend avoiding puddles and use gravity to spread the mixtures out, rather than a “pancake pour” on a level surface.

– Mike Townsend

Hi,

Can you give me some direction to the amount of prepared flow paint I need for the size of the canvas or board? I am moving into large pieces and don’t know how much paint to prepare.

oz/sq in would be very helpful. Even a range..

Hello, Patti.

Thanks for your questions.

Although the true response depends on how much you tilt and manipulate the panels, I’d suggest preparing 3 or 4 ounces per square foot. Also, appreciate that you can make mixtures and store them if you don’t use them that day.

– Mike Townsend

Thank you Mike. And during the holidays to boot. I LOVE THIS SITE.

Patti

You are most welcome Patti!

– Mike

Love all your info. I’ve been pouring since summer and really enjoy this! Hopefully I will be soon instructing this here in my home town. I have appointments with a few places here including the college. I have not used any of these products yet but will be soon. I requested some samples today. Can’t wait to see what comes. Your videos are wonderful also. Thanks. Cathy

Hi Cathy.

Thank you for your kind words!

Best of luck with your testing and the classes. Be sure to share your work on our Facebook page, Goldenpaints.

– Mike Townsend

Thank you so much for another fabulously informative article. I am planning a huge canvas pour of abstract flowers with perhaps some resin areas and was thinking I’d have to get some more Liquitex pouring Medium. Now I can save my money as I have a large bottle of GAC800, your generosity of information and fantastic products is what keeps me returning time and again to Golden 😍😘

I am curious to know if i could add water to extend the paint mixture and what effect that would have on each of the Golden paints. I’m about to try them with the Gac 800. With thanks

Hello Patricia.

You can add water with most acrylic paints and mediums. If you pour thickly however, you’ll likely end up with crazes during drying.

– Mike Townsend

Hello Michael

Very informative, I cant wait to try this product out, as have been pouring recently with

poor results. (no pun intended)

Hi Michael,

May I ask a question about adding paper collage pieces over the top of a pour and the best way to attach the paper? I have used Golden fluid paints and Floetrol. My pour is on a cotton canvas and has been curing for 4 days. I added silicon to my pour. I haven’t talc/washed it yet to remove the silicone. I have some artwork on fairly thick paper (made for acrylic paint) I would like to glue it on top of my pour.

Should I gesso the back of the paper, allow to dry and apply PVA directly to the paper? Would I need to prepare the paint on the canvas also?

I will try using GAC 800 from now on after reading your article. Do you know where I can buy it in Poole, Dorset, UK? Many thanks for any advice you may be able to offer.

Hello Josephine.

Thank you for your questions.

You’ll want to remove the silicone as best as you can, as it tends to create surface that doesn’t accept additional paint layers or topcoats.

Assuming you can apply a coat of acrylic medium onto the poured surface and it adhere’s well, you can then use either PVA glue or an acrylic medium as your collage glue. Fluid Matte Medium is a standard product for this application, however, you may desired the clarity of a gloss medium do it doesn’t obscure the pour. We have a video about collage, with several methods: https://www.youtube.com/watch?v=PCPO-VJQB1s I prefer the method #2 for thinner papers (at 1:30 mark on the video). Please let us know if you have any other questions.

– Mike

I’ve had really good luck spraying denatured alcohol on the surface of a pour to completely eliminate bubbling (either GAC 800 mixed with pigment or as an isolation coat).

It Certainly beats hovering over your work with a bobby pin.

Hi Sean.

Yes, it does aid in popping the bubbles and probably gets many more than you would even see. It can affect the smoothness of the color pours unless it’s a solid color but I tend to like the fine lace pattern that results. Thanks for your comments!

– Mike Townsend

I Mike,

I am new in Pouring acrylic paint over Canvases..

I like to have the famous CELLS formation during a dirty pour (several colors of paints in a single glass).

I just flip the glass over and let the paint run until the canvas is covered.

Which is the best combinations to use to achieve the CELLS FORMATION –

It is acrylic paint + floetrol + Gac 800 + Isopropyl alcohol

or is something different…….I tried on several canvas, different combinations but NO CELLS FORMATION.

I like to star doing Cells Formation with my 2 granddaughters,….they love the results we see on YouTube.

Hello Mario.

Thank you for your comments.

It’s hard to know why you are not getting the cell patterns in your work without knowing your recipe, but each paint mixture needs to be created individually first, and should be readily pourable, so test this first. Then you can do small pours of one color over another and see if any of the mixtures are not working. Once you get each color dialed in, then carefully layer several colors in a cup. The poured product should be moved around onto the canvas by tilting it to spread it around. If you don’t get cells after doing this, at the very end you can flick a little alcohol onto the surface. Be VERY careful using isopropyl alcohol and floetrol, and even acrylic paints and GAC 800 around children. They should not touch any of the paints while working and you should be the one to mix the materials together.

– Mike Townsend

Hej Michael,

excellent article, thanks for your effort continuously to give us new information about the use of GAC800.

I have a question:

If you use GAC800 with the High-Flow colors in 20:1, sometimes the mix still is a bit thick.

What medium would you recommend to use to thin the mix without losing binding strength?

BR Michael

https://artbylonfeldt.dk

How does GAC800 behave without added pigment? Is it essentially a slightly foggy transparent, or pretty opaque. How deep can I pour it straight without crazing?

Hi Michael,

All pretty informative. Thanks for the effort and insights.

My question would be that I seem to use GAC800 in the wrong way.

I use it as the last 10% in a medium with 60% PVA glue and 30% water. I added it instead of 10% Floetrol which caused the pour to get trapped bubbles and little white specks.

Would GAC800 still do its thing in this setup?

Or let’s put it the other way around.

To keep our pouring hobby affordable we use PVA glue, thin it down with water to make it pourable and ad some stabilizer to make it all work. What would you suggest would a good mix be with PVA glue and possibly GAC800?

Is there any other, better product for this?

Regards, Jan.

Hello Jan.

Thank you for your questions.

The GAC 800 is meant for use as the main painting medium. If you blend it with a PVA glue, the two products should mix well together, but it isn’t going to impact the glue the same as Flood’s Floetrol paint additive. Therefore blending the PVA with GAC 800 is just mixing two binders together. The Floetrol adds retarders and flow improvers, and surfactants which facilitate the development of cells. I have added isopropyl alcohol into the paint to help generate cells and other patterns, but it the pigment density should also be factored in. The only branded product we have that would be similar is the GOLDEN Airbrush Medium. However, I have not done any testing using the Airbrush Medium as an alternative to Floetrol, so it is just a guess as to what to try.

– Mike Townsend

I have a bottle of GAC 900 that I won’t ever use. Should I see if I can exchange it for 800 or do you think I could get decent results from doing a pour with GAC 900?

Hello Tanya.

Thanks for your question.

The GAC 900 would result in a very sticky poured surface, so you would be much better off swapping it for the GAC 800 or Color Pouring Medium Gloss.

Regards,

– Mike Townsend

Hi Michael. I am new to all of this. I have Goldens gloss pouring medium and Golden’s fluid acrylics. Do I need the GAC 800 instead of the pouring medium?

Hi Stephanie!

Nope. You can swap out the GAC 800 with the Pouring Medium Gloss without much of a difference. You are ready to paint!

– Mike Townsend

. Hi Michael. I really liked how you lucidly explained everything. I am a beginner but really want to learn. I have RM and Floetrol tell me please how can I dilute them correctly in what proportions? And I also tried PVC glue + varnish but nothing worked. Help to achieve a good result. thank

Hello Tatjana.

Thank you for your kind words and questions. What are you referring to as “RM”? Floetrol is a paint additive, and it depends on how you want to use it. If you use it the way the manufacturer “Flood” suggests, it’s around 20% max. If you are adding it to paints to create cells, then it’s hard to know how much to use until you make some mixes and test, because every color and type of paint will respond differently. Keep testing and take good notes!

– Mike Townsend