Was könnte für die Langlebigkeit eines Gemäldes wichtiger sein als die richtige Wahl und Vorbereitung des Untergrunds, auf dem Sie arbeiten? Da wir ein großes Interesse am Erfolg der Künstler haben, die unsere Produkte verwenden, möchten wir einige der Bedenken hervorheben, die auf dem Gebiet der Konservierung in Bezug auf die Oberflächenkrakelierung und die Verwendung von Sperrholz als Kunstmaterial bestehen. Wir bieten ein paar mögliche Erklärungen für dieses Phänomen und ein paar Vorschläge, wie man die Wirkung der Oberflächenkrakelierung abmildern kann. Beginnen wir jedoch zunächst mit ein paar Hintergrundinformationen darüber, wie Sperrholz hergestellt wird, um ein wenig Kontext zu vermitteln.

Sperrholz und die Entstehung von Oberflächenkrakelierung

Wenn wir von Sperrholz sprechen, meinen wir technisch veränderte Holzprodukte, die durch die kreuzweise Verklebung von Furnier oder dünnen Holzscheiben unter Hitze mit Druck und unter Verwendung starker Klebstoffe hergestellt werden. Der wichtigste Vorteil dieser Konstruktion ist, zumindest im Hinblick auf Maluntergründe, ihre Formbeständigkeit und ihre Widerstandsfähigkeit gegen Bewegung, wenn sie Schwankungen in Luftfeuchtigkeit und Temperatur ausgesetzt ist. Die kreuzweise verklebte Struktur sorgt gewissermaßen für eine „Zwangsstabilität“, die zwar zu den gewünschten strukturellen Eigenschaften führt, jedoch auch der Grund für viele Bedenken rund um Sperrholz ist.

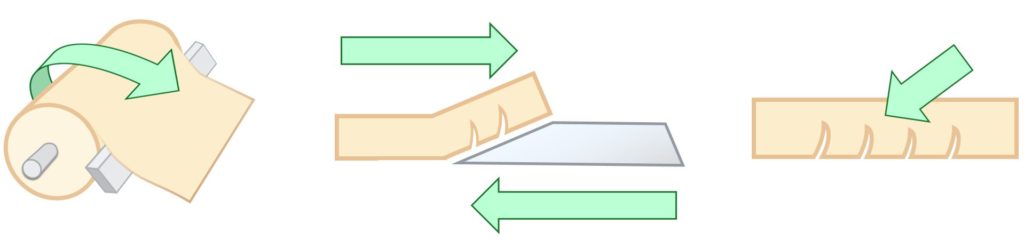

Das meiste Sperrholzfurnier wird mit Rundschälmaschinen hergestellt, wobei ein Holzstamm entweder durch Kochen oder Dämpfen aufgeweicht und dann auf einer Schälmaschine befestigt und ausbalanciert wird, wo dann durch ein feststehendes Schälmesser spiralförmig dünne Scheiben Furnier von dem rotierenden Holzstamm geschält werden. Wenn das Messer in das Holz eindringt und das Furnier vom Baumstamm trennt, wird das Holz unter enormen Scherkräften tangential gebogen. Die dadurch entstehende Belastung kann die Stärke des Holzes übersteigen und zu Fehlern in Form von Schälrissen führen. Alle Belastungen durch diesen Vorgang bleiben dann im Sperrholz erhalten, wenn das Furnier flach gelegt, miteinander verbunden und mit Klebstoff gebändigt wird.

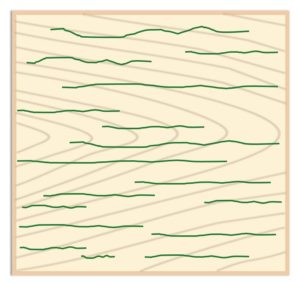

Die Klebstoffe selbst bieten einen gesteigerten Widerstand gegen Feuchtigkeit, was zu einer besseren Formbeständigkeit führt, doch das Holz ist nach wie vor hygroskopisch (oder „wasserliebend“) und möchte mit seiner Umwelt Feuchtigkeit austauschen. (Minor, M. 1993) Wenn diese Fluktuationen auftreten oder als Nebeneffekt von wasserbasierten Farben oder Grundierungen verursacht werden, führt dies zum Anschwellen und Schrumpfen des fixierten Holzes. Diese Fluktuation kann genügend Spannung erzeugen, um die Splitterbeständigkeit des Sperrholzes, bekannt als sein Bruchwiderstand, zu überwinden. Da Holz von Natur aus dazu tendiert, den einfachsten Weg zu finden, um diese Belastung zu verringern, können sich diese Schälrisse, die eine Schwäche im Furnier darstellen, öffnen und für größere Oberflächenrisse entlang der Holzmaserung sorgen. Wenn das Ausmaß der Krakelierung die Flexibilität der Grundschichten übersteigt, kann sie in Form von kleinen Rissen sichtbar werden und sich auch auf die darauffolgenden Farbschichten übertragen.

Die schlechte Nachricht

Leider kann man nicht viel tun, um eine Oberflächenkrakelierung zu reparieren, wenn sie einmal aufgetreten ist. Es besteht das Risiko, dass ein Auffüllen dieser Risse eine zusätzliche Belastung für das Holz bedeutet. (Minor, M. 1993) Zusätzliche Farbschichten, die die Risse abdecken sollen, wären ebenfalls anfällig für zukünftige Rissbildung, und es gibt in unserer Forschung keinen Beleg dafür, dass Finishes sich auf die Bildung einer Oberflächenkrakelierung auswirken könnten, außer dass sie diese vielleicht verlangsamen könnten. (Leavingood, S., Funck, J. W., Reeb, J. E., 2011) Versuche, das Sperrholz durch Hinzufügen einer Parkettierung noch weiter zu fixieren, könnten sogar zu noch mehr Belastung im Holz und damit zu einer Erhöhung des Risikos führen. Da die Krakelierung an einen Prozess gebunden ist, der bei der Herstellung allen Sperrholzes zwingend auftritt, könnte selbst hochwertiges Sperrholz eine Oberflächenkrakelierung aufweisen.

Welche Möglichkeiten gibt es?

Sperrholz ist alles andere als perfekt, aber dennoch für viele Künstler ein Standardmaterial, und das wird es auch noch lange Zeit bleiben, nachdem dieser oder andere Artikel veröffentlicht wurden. Es gibt ein paar Maßnahmen, durch die die Auswirkungen von Oberflächenkrakelierung gemildert werden können und die auch von Konservatoren unterstützt werden. Eine davon ist, Leinwand oder Papier auf die Deckschicht eines Bretts zu kleben. Dadurch können die Anzeichen der Maserung sowie die Auswirkung der Krakelierung auf Farbschichten reduziert werden, indem zwischen Gemälde und Untergrund eine Zwischenschicht eingebracht wird. Wir empfehlen häufig die Verwendung von MDO (Medium Density Overlay), einem Außensperrholz mit einer mit Harz imprägnierten Faser-Deckschicht, die ähnlich funktioniert. Einige Untersuchungen deuten darauf hin, dass der im Sperrholz verwendete Klebstoff ebenfalls eine entscheidende Rolle bei der Entwicklung einer Oberflächenkrakelierung spielen könnte, wobei wasserbeständige Harnstoff-Formaldehyd-Klebstoffe (UF-Klebstoffe) anfälliger sind. (Tremblay, C. Bouffard, J. F. 2012) Das Phenolharz, das zur Sättigung der Deckschicht in MDO und zum Verkleben des Furniers verwendet wird, ist ein wasserfester Klebstoff, der eine bessere Feuchtigkeitsbeständigkeit bietet, die dazu beitragen könnte, die Auswirkungen von Umwelteinflüssen oder Farben und Grundierungen auf Wasserbasis auf den Feuchtigkeitsgehalt des Bretts zu reduzieren. Außerdem können Maßnahmen ergriffen werden, um die relative Feuchtigkeit im Atelier zu stabilisieren oder zu steuern, wodurch die Schwankungen, die zur Rissbildung führen können, reduziert werden. Selbst die Wahl eines höherwertigen Sperrholzes mit weniger Hohlräumen und aus einer weniger porösen Holzart kann die Möglichkeiten verringern, dass Schälrisse an die Oberfläche des Furniers wandern. Wenn der wichtigste Aspekt der eines starren Untergrunds ist, gibt es viele technisch veränderte Holzalternativen, Metalluntergründe und verschiedene Acryltafeln, die sich ebenfalls eignen. Hier finden Sie zusätzliche Informationen zu MDO und ein kurzes Video, das den Vorgang des Aufklebens von Papier auf ein Brett zeigt:

Medium Density Overlay

Adhering Paper to Panel

Mit der Zeit, wenn unsere Forschung fortschreitet und wir einen umfassenderen Dialog mit Künstlern und Konservatoren aufbauen, werden wir häufig vergangene Empfehlungen im Lichte neuer Erkenntnisse neu bewerten müssen. Dies ist einer dieser Fälle, und während wir dazulernen und unsere Ratschläge aktualisieren, möchten wir unser Wissen teilen, in der Hoffnung, dass es dazu dient, Künstler über mögliche Risiken für die Langlebigkeit ihrer Werke zu informieren. Falls Sie Fragen oder Kommentare zu diesem Artikel oder anderen Themen rund um Farben haben, können Sie sich gerne unter EUhelp@goldenpaints.com oder telefonisch unter 0049 (0)69-348 72 154 an unser Material und Anwendungsberatung wenden.

Verweise:

- College of Forestry, Oregon State University. (2018) Maple Veneer Checking Research. Retrieved from: http://owic.oregonstate.edu/maple-veneer Accessed on March 11, 2019.

- Forbes, C. (1997) Understanding and Minimizing Veneer Checking on Furniture Panels. NC State Extension Publications. Accessed on March 11, 2019.

- Klim, Susan (1990). Composite Wood Materials in Twentieth Century Furniture. The Conservation Information Network. Retrieved at http://www.wag-aic.org/1990/WAG_90_klim.pdf

- Leavingood, S., Funck , J. W., Reeb, J. E. (2011) A Note on Face Veneer Checking in Maple Plywood, International Wood Products Journal. 2:@, 120123.http://dx.doi.org/10.1179/2042645311Y.0000000010

- Minor, M. (1993) The Nature and Origin of Surface Veneer Checking in Plywood. Department of Objects Conservation, The Metropolitan Museum of Art, New York, N.Y.

- Tremblay, C. Bouffard, J. F. (2012) Study on the Issue of Veneer Cracking in the Kitchen Cabinet and Furniture Industry. Natural Resources Canada, Forestry Canada and Economic Development Canada. Value to Wood Report FPI-11-01. Project No. 201005269.

1 Gedanke zu „Oberflächenkrakelierung und Sperrholz – ein Grund zur Sorge?“