Eine von vielen Wänden mit Prüfmustern, die im Oktober nach Arizona verschifft werden, um dort drei Monate lang Lichtechtheit im Außenbereich nach dem ASTM D4303 Verfahren zu testen.

Eine von vielen Wänden mit Prüfmustern, die im Oktober nach Arizona verschifft werden, um dort drei Monate lang Lichtechtheit im Außenbereich nach dem ASTM D4303 Verfahren zu testen.

Wir berichten zwar oft über die Ergebnisse von Lichtechtheitsprüfungen, aber wir haben uns selten die Zeit genommen, den Prozess zu beschreiben, den wir anwenden. Und seien wir ehrlich: Für die meisten Menschen ist die Aussage, dass unsere Tests der ASTM D4303, Standard Test Methods for Lightfastness of Colorants Used in Artists’ Materials, entsprechen, wenig aussagekräftig. Um das zu ändern, beschreiben wir im Folgenden die wichtigsten Schritte, die wir unternehmen, sowie die Wege, die wir eingeschlagen haben, um diese Art von Tests zu verbessern und robuster zu machen.

Probenvorbereitung

Für Acrylfarben erstellen wir 0,25 mm Farbabzüge auf grundierten Aluminiumplatten sowie auf lackierten Testkarten. 0,25 mm sind etwa so dick wie 3 Blatt Kopierpapier. Die Aluminiumplatten werden für Proben in Außenprüfanlagen verwendet, während der Karton für beschleunigte Tests in Innenräumen gedacht ist. Ölfarben folgen der gleichen Reihe von Schritten, verwenden aber eine andere Grundierung für die Aluminiumplatten und werden mit einer Dicke von 0,15mm (~2 Blatt Papier) hergestellt. Aquarellfarben hingegen werden als eine schnell hergestellte Lasur über ein spezielles Filterpapier aufgetragen, das sowohl für Innen- als auch für Außentests geeignet ist.

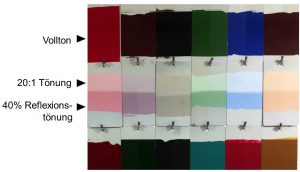

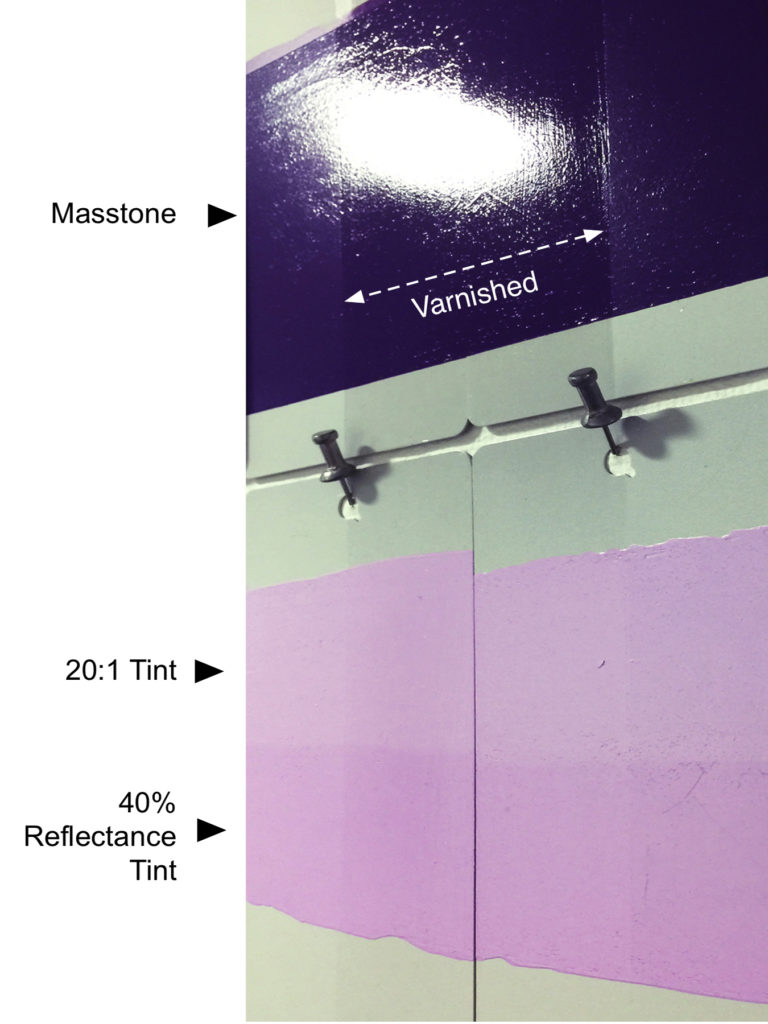

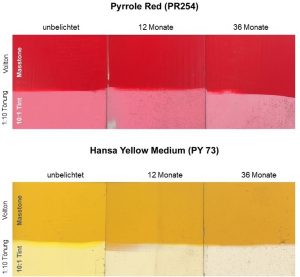

Was nur wenige wissen, ist, dass die ASTM-Lichtechtheitswerte immer auf einer Weißtönung und nicht auf dem Vollton einer Farbe basieren. Der Grund dafür ist ganz einfach: Pigmente sind in einer Tönung in der Regel anfälliger, und du willst sicherstellen, dass sie auch dann lichtecht bleiben, wenn sie mit Weiß gemischt werden. Auch der Grad der Abtönung ist sehr spezifisch. Öl- und Acrylfarben müssen mit so viel Weiß bzw. Wasserfarben mit so viel Wasser gemischt werden, dass sie bei der Wellenlänge der maximalen Absorption einen Reflexionsgrad von 35-45% erreichen. Wenn das kein kristallklares Bild in deinem Kopf hervorruft, bist du nicht allein! Hoffentlich hilft dir dieses Bild von Testmustern:

Anzahl der Proben

Für die Lichtechtheitsprüfung verlangt die ASTM insgesamt 7 identische Farbtöne für jede Farbe: eine unbelichtete Kontrolle, dann drei für die Außen- und drei für die beschleunigte Innenbelichtung. Wenn wir jedoch ein neues Pigment, einen neuen Pigmentlieferanten oder eine wesentliche Änderung in der Rezeptur testen, schließt GOLDEN fast immer auch die Volltöne mit ein. Außerdem haben wir vor kurzem damit begonnen, zusätzliche blassere 20: 1 Tönungen sowie mit einem UV-filtrierenden Firnis beschichtete Flächen hinzuzufügen. Diese stark erweiterten Muster geben uns eine viel breitere Basis für die Bewertung eines Pigments und dafür, wie sich eine bestimmte Farbe unter verschiedenen Umständen verhält. Für die Zwecke der ASTM sind jedoch nur die Ergebnisse dieser ursprünglichen Farbtönungen wirklich wichtig. Alles andere haben wir hinzugefügt, um die Leistung eines Pigments auf einer tieferen Ebene zu verstehen.

Außen- und beschleunigte Innen-Xenon-Belichtung

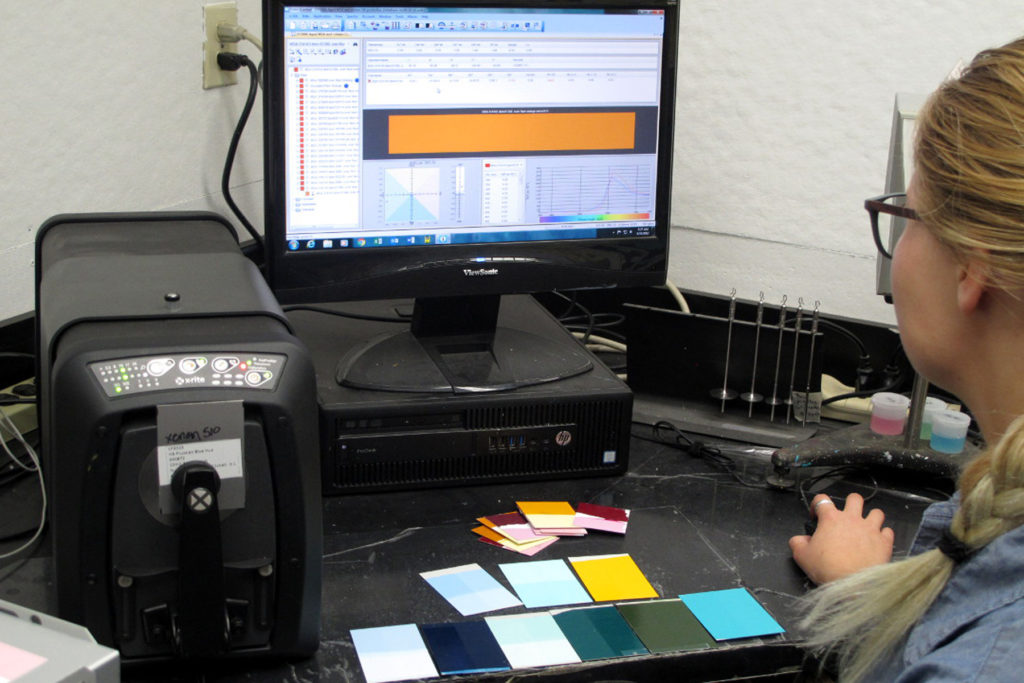

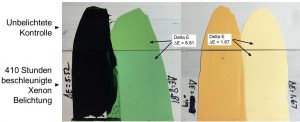

Nachdem sie vollständig getrocknet sind, werden die Proben mit einem Spektrophotometer an drei verschiedenen Stellen abgelesen, die dann gemittelt werden, um eine Aufzeichnung der Farbe beim Start zu erhalten. Die Außengruppe wird dann zu einer Testanlage in Südflorida oder Arizona geschickt, wo sie unter Glas in einem Winkel von 45 Grad zur Sonne aufgestellt wird. Die beschleunigte Innengruppe wird in eine Xenon Lichtalterungsmaschiene gebracht, die die gleiche Spektralkurve wie Sonnenlicht durch Fensterglas simuliert. Die Proben im Freien müssen irgendwann zwischen Oktober und März ausgesetzt werden und werden so lange belassen, bis sie eine Gesamtsonneneinstrahlung von 1260 MJ/m² erreichen, was etwa 3 Monate dauert. Diese Bestrahlungsstärke wurde ursprünglich von der ASTM gewählt, weil sie Ergebnisse lieferte, die dem Grad des Verblassens von verschiedenen Pigmenten wie Alizarin-Karminrot und Krapprot entsprechen, die in historischen Gemälden zu finden sind, die über ein Jahrhundert alt sind. Die Proben in der Xenon Lichtalterungsmaschiene werden der gleichen Menge an UV-Strahlung ausgesetzt wie die Proben im Freien, aber in einem kürzeren Zeitrahmen, der nach 410 Stunden abgeschlossen ist.

Auswerten der Ergebnisse

Nachdem die Proben ihre Tests abgeschlossen haben, werden sie erneut dreimal mit einem Spektrophotometer abgelesen, die Werte gemittelt und der Grad der Veränderung gegenüber den ursprünglichen Werten berechnet. Die Ergebnisse werden dann in der Einheit Delta E (ΔE) angegeben. Theoretisch entspricht ein einzelnes Delta E der kleinsten visuellen Veränderung, die ein normaler Beobachter erkennen kann. Farben mit einem Delta E zwischen 1 und 4 erhalten die ASTM-Lichtechtheitsbewertung I (ausgezeichnet), zwischen 4 und 8 die ASTM-Lichtechtheitsbewertung II (gut) und zwischen 8 und 16 die Lichtechtheitsbewertung III (mittelmäßig). Mehr dazu erfährst du in unserem früheren Just Paint-Artikel Delta E: Ein Schlüssel zum Verständnis von Lichtechtheitsmessungen.

Andere Lichtechtheitsprüfungen

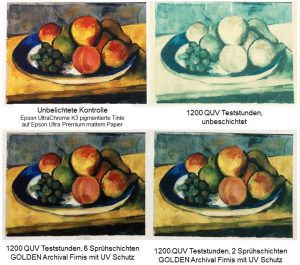

Neben der ASTM-Norm führt GOLDEN auch eine Reihe anderer Lichtechtheitsprüfungen durch. Um zum Beispiel zu sehen, wie sich Farben in Außenbereichen wie Wandmalereien verhalten, schicken wir regelmäßig mehrere Muster nach Südflorida, wo sie ohne Glas angebracht und vollständig einer hohen Luftfeuchtigkeit und wechselnden Außenbedingungen ausgesetzt werden. Diese werden dann in Abständen von 6, 12, 24 und 36 Monaten bewertet. Außerdem testen wir regelmäßig Farben, Firnisse, verschiedene Collage- und Zeichenmaterialien und eine Vielzahl anderer Produkte in einer anderen Lichtechtheitskammer, die QUV genannt wird und in der die Proben dem Licht von speziellen fluoreszierenden UV-A-Lampen ausgesetzt werden. Diese entsprechen zwar nicht dem breiten Spektrum des Sonnenlichts im Freien oder von Xenon, aber sie ahmen die zerstörerische UV-Komponente des Lichts, das durch Fensterglas fällt, genau nach. Die Proben werden Zyklen von 400 Stunden ausgesetzt, wobei 3 Zyklen ungefähr den Ergebnissen entsprechen, die wir bei Tests im Freien und mit Xenon sehen.

.

Diese Studie untersuchte die Wirksamkeit unserer Archival und MSA Firnisse zum Schutz eines Inkjet-Drucks mit pigmentierten Tinten, welches unter ähnlichen Bedingungen aufbewahrt wurde wie bei einem Gemälde erwartet werden könnte.

Diese Studie untersuchte die Wirksamkeit unserer Archival und MSA Firnisse zum Schutz eines Inkjet-Drucks mit pigmentierten Tinten, welches unter ähnlichen Bedingungen aufbewahrt wurde wie bei einem Gemälde erwartet werden könnte.

Über das Erforderliche hinausgehend

Nachdem wir das alles beschrieben haben, findest du es vielleicht überraschend zu erfahren, dass keiner dieser Tests von einem Hersteller verlangt wird. Wir sind zwar der Meinung, dass jeder Hersteller diese Tests durchführen sollte, aber die ASTM-Normen erlauben es den Farbenherstellern, ihren Produkten einfach eine Tabelle mit den Lichtechtheitswerten zuzuweisen. Diese Tabelle enthält Pigmente, die irgendwann einmal ASTM-Tests unterzogen und vom Ausschuss mit einer Lichtechtheitsbewertung versehen wurden. Die meisten dieser Tests wurden jedoch vor mehr als 30 Jahren durchgeführt und oft nur mit einer einzigen Pigmentquelle oder Farbmarke. Aus unserer eigenen Erfahrung, die wir seit den frühen 80er Jahren mit der regelmäßigen Prüfung von Farben gemacht haben, glauben wir, dass dies nicht ausreicht. Die Qualität der Pigmente kann schwanken, und Tests, die vor so langer Zeit durchgeführt wurden und nur eine begrenzte Auswahl enthielten, sind möglicherweise nicht repräsentativ für das, was ein bestimmter Hersteller derzeit verwendet. GOLDEN ist der Meinung, dass es für jedes Unternehmen wichtig ist, diese Tests durchzuführen, um sicherzustellen, dass seine Produkte wirklich lichtecht sind.